Catherine Östlund

Partner: Innventia, Stockholm

Funding: VINNMER programme, Swedish Governmental Agency for Innovation Systems

Period: 0901-

Abstract: Studies of paper sheet structure characterisation, e.g. the distribution of fibres, fibre flocs and the void areas between them, can be made using beta radiography or by splitting the paper in layers and study each layer, or by studying the cross-section of the paper. The three-dimensional (3D) structure of the sheet can from such data in some cases be estimated. The focus of this research project is to propose 3D paper structure analysis methods based on image analysis, and to compare the results from two-dimensional analysis methods to those achieved with a 3D method. An X-ray microtomograph is used for studying 3D images.

Erik Wernersson, Anders Brun, Joakim Lindblad, Cris Luengo, Catherine Östlund, Gunilla Borgefors

Partners: Norwegian Pulp and Paper Research Institute, Trondheim, Norway; Innventia, Stockholm; Dept. of Engineering Sciences, Applied Mechanics, UU; Dept. of Physics, University of Jyväskylä (UJ), Finland; SINTEF Materials and Chemistry, Norway; University of Novi Sad, Serbia

Funding: S-faculty, SLU; WoodWisdom-Net

Period: 0406-

Abstract: The internal structure of paper is important because many of its properties correspond directly to the properties of single fibres and their interaction in the fibre network. How single fibres in paper bond and how this affects paper quality is not fully understood, since most structure analysis of paper has been performed in cross-sectional, two-dimensional (2D) images whereas paper is a complex, three-dimensional (3D) structure.

Another application for wood fibres that has recently gained interest is wood polymer composite materials. The properties of these materials do not only depend on the structure of the fibre network, but also on the interaction between the fibres and the polymer matrix surrounding the fibres. Advances in imaging technology have made it possible to acquire 3D images of paper and wood polymer composite materials. In this project, image analysis methods for characterizing the 3D material structure in such images are developed. The detailed knowledge of the material structure attainable with these methods is useful for improving material properties and for developing new materials.

The project objective is to achieve a complete segmentation of individual fibres and pores in volume images of the material. Given such a segmentation, any desired measurement of the internal structure is available. Measurements on individual fibres and the structural arrangement of fibres can then be related to macroscopic material properties.

In this project, different volume images of paper and composite materials are available: one volume created from a series of 2D scanning electron microscopy (SEM) images at StoraEnso, Falun; and X-ray microtomography volume images of paper and composite samples imaged at the European Radiation Synchrotron Facility (ESRF) in Grenoble, France, at the Paul Scherrer Institut (PSI) in Villigen, Switzerland and also from tabletop scanners at University of Jyväskylä, Finland and Innventia, Stockholm.

Two papers were submitted during 2011, one on measuring the fibre length distribution in composites from micro-CT images, and one on swelling of fibres in a composite due to moisture uptake. An overview article on characterization of nanofibrillated wood fibres appeared in the book Nanocomposites and Polymers with Analytical Methods.

Erik Wernersson, Cris Luengo, Anders Brun, Catherine Östlund, Gunilla Borgefors

Partners: Norwegian Pulp and Paper Research Institute (PFI), Trondheim, Norway; Innventia, Stockholm; Dept. of Engineering Sciences, Applied Mechanics, UU; Dept. of Physics, University of Jyväskylä (UJ), Finland; SINTEF Materials and Chemistry, Norway; Risø National Laboratory, Technical University of Denmark

Funding: S-faculty, SLU; WoodWisdom-Net

Period: 0901-

Abstract: It is of great importance to evaluate the performance and stability of new methods. It is often hard to do so, when working with natural materials, since no true answer is available. With this project we aim to create highly realistic reference images that can be used to evaluate new and existing methods designed for characterisation of fibrous materials from µCT.

Within the project, methods have been developed to generate and pack synthetic wood fibres as well as to simulate µCT acquisition systems with characteristic artifacts.

Erik Wernersson, Cris Luengo, Anders Brun, Gunilla Borgefors

Partners: Jan Van den Bulcke, Dept. of Forest and Water Management, Ghent University, Belgium

Funding: S-faculty, SLU

Period: 1009 -

Abstract: When imaging wood based materials, diffraction causes artifacts especially around sharp edges. In this project, different ways to reduce such artifacts are investigated, especially in already reconstructed images.

Bettina Selig, Cris Luengo, Gunilla Borgefors

Partners: Stig Bardage, SP Technical Research Institute of Sweden; Geoffrey Daniel, Dept. of Forest Products, SLU

Funding: S-faculty, SLU

Period: 0709-

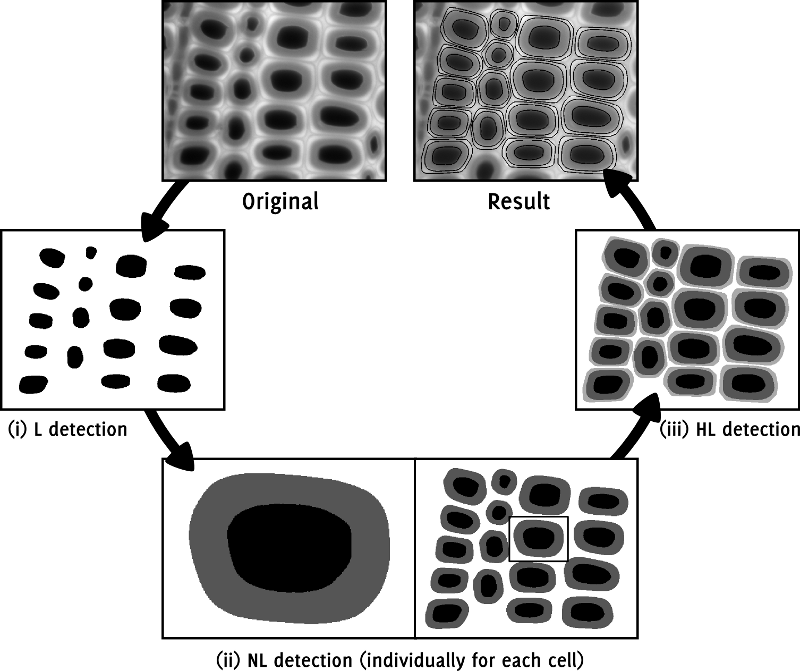

Abstract: Abnormal wood known as compression wood is present in almost every softwood tree harvested. Compression wood fibers have different mechanical properties and therefore they are considered detrimental for both construction wood and pulp and paper purposes. With a UV-light microscope we can analyze the lignin distribution in wood fiber walls and therewith quantify the quality of the wood fibers. In this project we develop an automatic method that detects and delineates softwood fibers. It divides the cells into lumen (L), normally lignified (NL) and highly lignified (HL) areas, see Figure 13. For this algorithm we use among others a two stage-snake described in our paper "Segmentation of Highly Lignified Zones on Wood Fibre Cross-Sections" that we presented at SCIA 2009 in Oslo. This year, we evaluated our method on both pine and spruce compression wood images and submitted our results to a journal for publication.

|