Catherine Östlund

Partner: Innventia, Stockholm

Funding: VINNMER programme, Swedish Governmental Agency for Innovation Systems

Period: 0901-

Abstract: Studies of paper sheet structure characterisation, e.g. the distribution of fibres, fibre flocs and the void areas between them, can be made using beta radiography or by splitting the paper in layers and study each layer, or by studying the cross-section of the paper. The three-dimensional (3D) structure of the sheet can from such data in some cases be estimated. The focus of this research project is to propose 3D paper structure analysis methods based on image analysis, and to compare the results from two-dimensional analysis methods to those achieved with a 3D method. An X-ray microtomograph is used for studying 3D images.

Erik Wernersson, Anders Brun, Joakim Lindblad, Cris Luengo, Catherine Östlund, Gunilla Borgefors

Partners: Norwegian Pulp and Paper Research Institute, Trondheim, Norway; Innventia, Stockholm; Dept. of Fibre and Polymer Technology, Royal Institute of Technology, Stockholm; Dept. of Physics, University of Jyväskylä (UJ), Finland; SINTEF Materials and Chemistry, Norway; Risø National Laboratory, Technical University of Denmark, Faculty of Engineering, University of Novi Sad, Serbia

Funding: S-faculty, SLU; WoodWisdom-Net

Period: 0406-

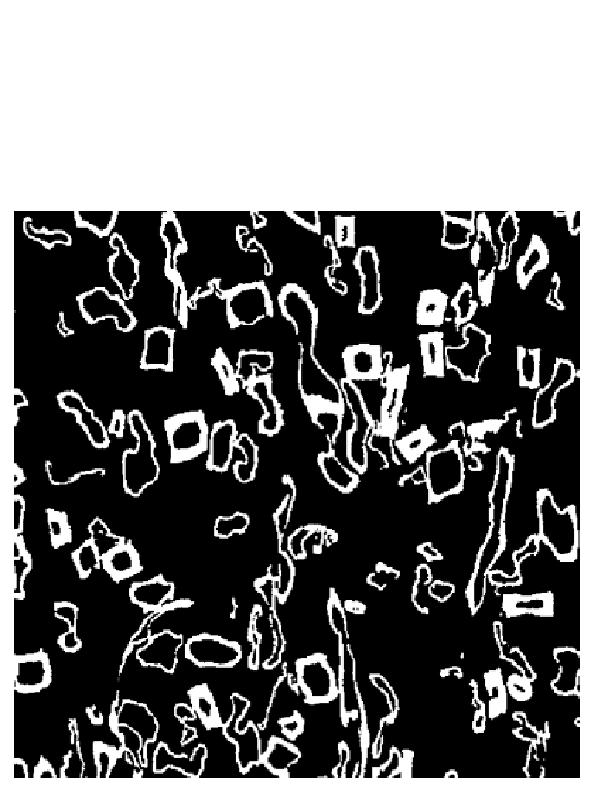

Abstract: The internal structure of paper is important because many of its properties correspond directly to the properties of single fibres and their interaction in the fibre network. How single fibres in paper bond and how this affects paper quality is not fully understood, since most structure analysis of paper has been performed in cross-sectional, two-dimensional (2D) images whereas paper is a complex, three-dimensional (3D) structure, see Fig.

Another application for wood fibres that has recently gained interest is wood polymer composite materials. The properties of these materials do not only depend on the structure of the fibre network, but also on the interaction between the fibres and the polymer matrix surrounding the fibres.

Advances in imaging technology have made it possible to acquire 3D images of paper and wood polymer composite materials. In this project, image analysis methods for characterizing the 3D material structure in such images are developed. The detailed knowledge of the material structure attainable with these methods is useful for improving material properties and for developing new materials.

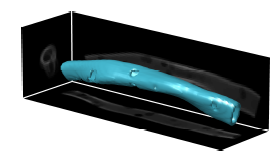

The project objective is to achieve a complete segmentation of individual fibres and pores in volume images of the material. Given such a segmentation, any desired measurement of the internal structure is available. Measurements on individual fibres and the structural arrangement of fibres can then be related to macroscopic material properties.

In this project, different volume images of paper and composite materials are available: one volume created from a series of 2D scanning electron microscopy (SEM) images at StoraEnso, Falun; and X-ray microtomography volume images of paper and composite samples imaged at the European Radiation Synchrotron Facility (ESRF) in Grenoble, France, at the Paul Scherrer Institut (PSI) in Villigen, Switzerland and during 2010 we have acquired several data with a tabletop scanner at University of Jyväskylä, Finland.

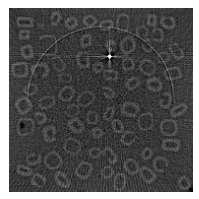

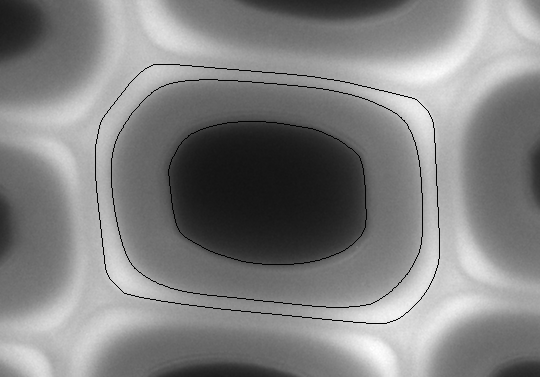

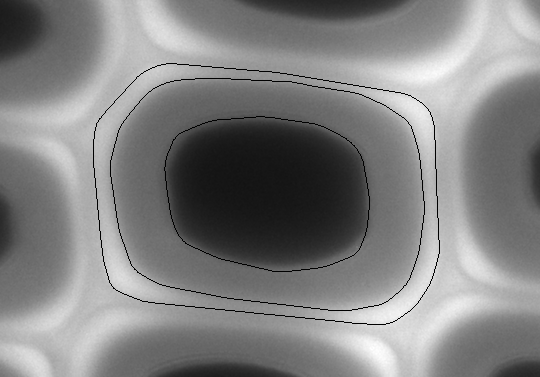

During 2010 further development of methods for de-noising of the

acquired image volumes was undertaken. A variational approach,

minimizing the image Total Variation by Spectral Conjugate Gradient

optimization, showed to outperform previously used SUSAN

filtering. The developed model for generating synthetic µCT

data ![]() facilitated objective performance

comparison. Results of this study were presented at the International

Conference on Pattern Recognition (ICPR) in August 2010 and some examples can be seen in Fig.

facilitated objective performance

comparison. Results of this study were presented at the International

Conference on Pattern Recognition (ICPR) in August 2010 and some examples can be seen in Fig. ![]()

|

|

Erik Wernersson, Cris Luengo, Anders Brun, Catherine Östlund, Gunilla Borgefors

Partners: Norwegian Pulp and Paper Research Institute (PFI), Trondheim, Norway; Innventia, Stockholm; Dept. of Fibre and Polymer Technology, Royal Institute of Technology, Stockholm; Dept. of Physics, University of Jyväskylä (UJ), Finland; SINTEF Materials and Chemistry, Norway; Risø National Laboratory, Technical University of Denmark

Funding: S-faculty, SLU; WoodWisdom-Net

Period: 0901-

Abstract: It is of great importance to evaluate the performance and stability of new methods. It is often hard to do so, when working with natural materials, since no true answer is available. With this project we aim to create highly realistic reference images that can be used to evaluate new and existing methods designed for µCT images of fibrous materials.

So far, the project has resulted in a method to generate and pack

synthetic wood fibres, and a software simulation of the µCT

acquisition system that is capable of reproducing characteristic

artifacts, see Fig, ![]() .

.

|

Erik Wernersson, Cris Luengo, Anders Brun, Gunilla Borgefors

Funding: S-faculty, SLU

Period: 1009 -

Abstract: Curvature is known as a useful local descriptor of 2D surfaces, embedded in 3D space with applications ranging from visualisation to segmentation. With this project, we aim to find elegant ways to calculate curvature directly from volumetric data which might be flawed with artifacts and noise. No intermediate surface representations are used to ensure stability. The methods will be useful in the analysis of microCT images of composite materials where curvature can be used as a descriptor of several local properties of wood fibres.

Bettina Selig, Cris Luengo, Gunilla Borgefors

Partner: Dept. of Forest Products, SLU

Funding: S-faculty, SLU

Period: 0709-

Abstract: The properties of wood fibers are important for the performance of wood and fiber products. Compression wood is of limited value in the forest product industry, since its fibers are stiffer and more difficult to collapse compared to normal wood. But because it is difficult to completely avoid compression wood a better understanding of it is needed in order to develop mathematical prediction models of wood mechanics.

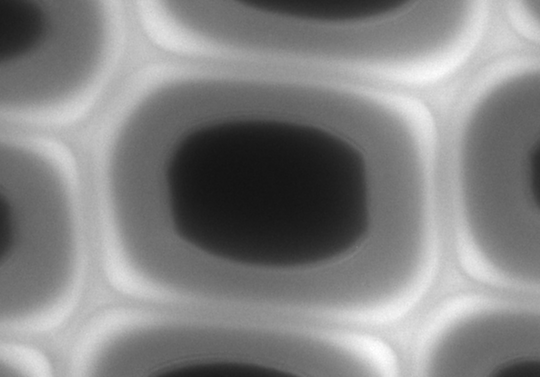

We have developed a method that automatically segments and measures

different attributes of wood fibers from fluorescence microscope

images of compression wood cross-sections. The results were compared

to manual segmentations defined by experts. Fig. ![]() shows an example for the automatic and manual delineation. The outer two segmentations lines (see Fig.

shows an example for the automatic and manual delineation. The outer two segmentations lines (see Fig. ![]() (a) and (c)) agreed to a satisfying degree. For the inner segmentation line (separating lumen and cell wall) the automatic

method set the boundary slightly further inward compared to the manual

delineation. This caused an systematic error which can be corrected

for. Descriptions of the algorithms and experiments were submitted for

journal publication.

(a) and (c)) agreed to a satisfying degree. For the inner segmentation line (separating lumen and cell wall) the automatic

method set the boundary slightly further inward compared to the manual

delineation. This caused an systematic error which can be corrected

for. Descriptions of the algorithms and experiments were submitted for

journal publication.

|

Cris Luengo

Partners: Lantmännen Lantbruk (Lidköping & Uppsala), Maxx automation AB (Uppsala)

Funding: Lantmännen Lantbruk

Period: 1006-

Abstract: In this project we have developed novel algorithms to assess the quality of a batch of grain (oats, barley, wheat) as it is fed through the Seedscanner 2003 seed sorting robot. The algorithms estimate the proportion of grains that are discolored, burned, sprouted, molded, or damaged on other ways. Development of these and other algorithms continues, as well as hardware modifications to the robot to improve the imaging.

Kristin Norell, Stina Svensson, Gunilla Borgefors

Partners: The Swedish Timber Measurement Council; Dept. of Forest Products and Markets, SLU

Funding: The Swedish Timber Measurement Council; S-faculty, SLU

Period: 0505 -

Abstract: The wood quality of a log can be determined to some extent by examining the log end. Such analysis is performed manually at sawmills, where a grader has a couple of seconds to determine features like the approximate annual ring density, presence of rot and presence of compression wood and at the same time take into account information about size and shape of the log as it passes on a conveyor. By using computerized image analysis, grading the number of annual rings can be more robust and take some work load off the grader. In this project, methods to measure properties of logs in saw mill environment using computerized image analysis is developed.

The images used are log end images of Norway spruce (Picea abies (L.) H.Karst) and Scots pine (Pinus sylvestris L.) captured in a sawmill environment. Logs are sawn with a regular harvester or chainsaw and stored for various times before imaging. The end faces are depicted using either a system camera or an a camera more suitable for industrial applications mounted at the measurement station at Setra Group Nyby sawmill.

Kristin Norell, Stina Svensson, Gunilla Borgefors

Partners: Kim Dralle, Anders Björholm Dahl, Dralle A/S, Copenhagen, Denmark

Funding: S-faculty, SLU; Stiftelsen Mauritz Carlgrens fond

Period: 0612 - 1005

Abstract: The focus of this project is image analysis methods for identifying rot in log end faces. The purpose is to detect rot already while harvesting, or when the logs are in a stack waiting for transport. Logs are depicted using a standard color digital camera that can be mounted on a harvester or a vehicle. The goal is to find a robust method for detecting rot in timber suitable for practical use.

Kristin Norell, Gunilla Borgefors

Partners: The Swedish Timber Measurement Council; Dept. of Forest Products and Markets, SLU

Funding: The Swedish Timber Measurement Council; SLU S-faculty

Period: 0901-1012

Abstract: A small dataset or lack of ground truth can be a problem when developing and evaluating image analysis methods. In such cases synthetic images can be useful as a complement to real data. In this project a generator for synthetic end face images was developed.

End face features are generated according to the procedure of tree growth, including annual rings, knots, heartwood and bark. Also other features are simulated, such as unevenness and roughness from harvesting, camera setup, illumination, and imaging, including colour noise due to Bayer filtering.