Maria Axelsson, Erik Wernersson, Anders Brun, Joakim Lindblad, Cris Luengo, Catherine Östlund, Gunilla Borgefors

Partners: Norwegian Pulp and Paper Research Institute (PFI), Trondheim, Norway; Innventia, Stockholm; Dept. of Fibre and Polymer Technology, KTH, Stockholm; Dept. of Physics, University of Jyväskylä (UJ), Finland; SINTEF Materials and Chemistry, Norway; Risø National Laboratory, Technical University of Denmark

Funding: S-faculty, SLU; WoodWisdom-Net

Period: 0406-

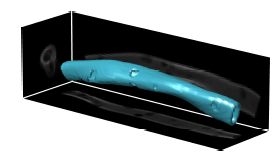

Abstract: The internal structure of paper is important because many material properties correspond directly to the properties of single fibres and their interaction in the fibre network. How single fibres in paper bond and how this affects paper quality is not fully understood, since most structure analysis of paper has been performed in cross-sectional, two-dimensional (2D) images and paper is a complex, three-dimensional (3D) structure, see Figure 15.

Another application for wood fibres that has recently gained interest is wood polymer composite materials. The properties of these materials do not only depend on the structure of the fibre network, but also on interaction between the fibres and the polymer matrix surrounding the fibres.

Advances in imaging technology has made it possible to acquire 3D images of paper and wood polymer composite materials. In this Project, image analysis methods for characterizing the 3D material structure in such images are developed. The detailed knowledge of the material structure attainable with these methods is useful for improving material properties and for developing new materials.

The Project objective is to achieve a complete segmentation of individual fibres and pores in volume images of the material. Given such a segmentation, any measurement of the internal structure is available. Measurements on individual fibres and the structural arrangement of fibres can then be related to macroscopical material properties.

In this Project, different volume images of paper and composite materials are available for the studies: one volume created from a series of 2D scanning electron microscopy (SEM) images at StoraEnso, Falun and X-ray microtomography volume images of paper and composite samples imaged at the European Radiation Synchrotron Facility (ESRF) in Grenoble, France, and at the Paul Scherrer Institut (PSI) in Villigen, Switzerland.

During 2009, the Project has resulted in a number of publications. A study on pore characterization of paper was published in Pattern Analysis and Applications. It includes new methods to characterize the pore network in paper materials and gives measurements that are important in understanding paper properties such as water absorption and print quality.

Two studies were presented at the 15th International Conference on Image Analysis and Processing. Among the results was a thorough study on how to select parameters when analyzing fibre directions of fibrous materials and a method to estimate the fibre radii of solid fibres and a novel segmentation algorithm.

We are also happy to announce that Maria Axelsson earned the PhD-degree with her dissertation Image Analysis for Volumetric Characterisation of Microstructure in March.

|

|

Erik Wernersson, Cris Luengo, Anders Brun, Catherine Östlund, Gunilla Borgefors

Partners: Norwegian Pulp and Paper Research Institute (PFI), Trondheim, Norway; Innventia, Stockholm; Dept. of Fibre and Polymer Technology, KTH, Stockholm; Dept. of Physics, University of Jyväskylä (UJ), Finland; SINTEF Materials and Chemistry, Norway; Risø National Laboratory, Technical University of Denmark

Funding: S-faculty, SLU; WoodWisdom-Net

Period: 0901-

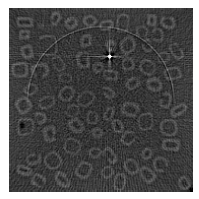

Abstract: It is of great importance to evaluate the performance and stability of new methods. Unfortunately, it is often hard to do so when working with natural materials. With this Project we aim to create highly realistic reference images that can be used to evaluate new and existing methods designed for µCT images of fibrous materials.

During this year, we developed a method to generate and pack synthetic wood fibres, and a software simulation of the µCT acquisition system that is capable of reproducing characteristic artifacts, see Fig, 16. Our paper, presented at the 6th International Symposium on Image and Signal Processing and Analysis, was the recipient of the best paper award.

Kristin Norell, Stina Svensson, Gunilla Borgefors

Partners: The Swedish Timber Measurement Council (VMR), Dept. of Forest Products and Markets, SLU

Funding: The Swedish Timber Measurement Council (VMR); S-faculty, SLU

Period: 0505 -

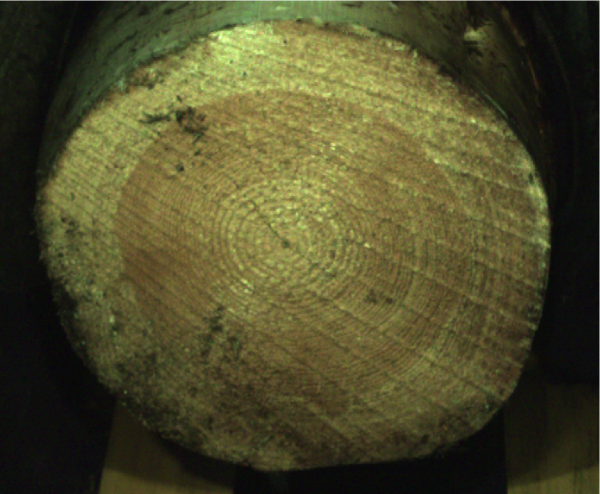

Abstract: The wood quality of a log can be determined to some extent by examining the log end. Such analysis is performed manually at sawmills, where a grader has a couple of seconds to determine features like the approximate annual ring density, presence of rot and presence of compression wood and at the same time take into account information about size and shape of the log as it passes on a conveyor. By using computerized image analysis, grading the number of annual rings can be more robust and take some work load off the grader. In this Project, methods to measure properties of logs in saw mill environment using computerized image analysis is developed.

The images used are log end images of Norway spruce (Picea abies (L.) H.Karst) and Scots pine (Pinus sylvestris L.) captured in a sawmill environment. Logs are sawn with a regular harvester or chainsaw and stored for various times before imaging. The end faces are depicted using either a system camera or an a camera more suitable for industrial applications mounted at the measurement station at Setra Group Nyby sawmill.

During 2009 a article on annual ring measurements was published at the International Conference on Image Analysis and Processing (ICIAP'09). In this paper the number of rings is measured automatically in images captured using the mounted camera. A direction suitable for measurements is detected using local orientation and the Grey weighted polar distance transform (GWPDT) is applied in the chosen area to outline the annual rings. For developing the method end faces with annual ring pattern that could be delineated by visual inspection at least on some region of the end face where picked out from a larger dataset.

A thorough evaluation of the annual ring measurements was started during 2009 by capturing a dataset using the mounted end face camera. An example of an image from the dataset is shown in Figure 17. This dataset contains end faces with higher number of annual rings compared to the end faces handled in previous research which makes the task even more difficult. The included end faces were graded at the sawmill measurement station by a grader and a grading inspector for comparison, and ground truth was determined by the grading inspector. Preliminary measurements show that the automatic method performs as well as the manual grader at the measurement station.

|

Kristin Norell, Gunilla Borgefors

Partners: The Swedish Timber Measurement Council (VMR), Dept. of Forest Products and Markets, SLU

Funding: The Swedish Timber Measurement Council (VMR), SLU S-faculty

Period: 0901-

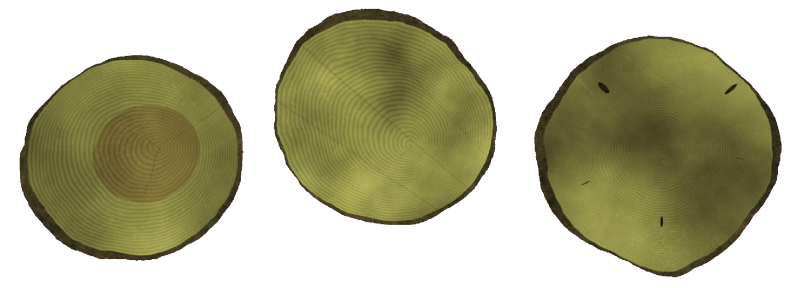

Abstract: A small dataset or lack of ground truth can be a problem when developing and evaluating image analysis methods. In such cases synthetic images can be useful as a complement to real data. In this Project a generator for synthetic end face images was developed.

End face features are generated according to the procedure of tree growth, including annual rings, knots, heartwood and bark. Also other features are simulated, such as unevenness and roughness from harvesting, camera setup, illumination, and imaging, including colour noise due to Bayer filtering.

An article was published during 2009 at the International Symposium on Image and Signal Processing and Analysis (ISISPA'09). Code for generating data was made public at http://www.cb.uu.se/~kristin/research.html together with synthetic images. Three of these images are shown in Figure 18.

Kristin Norell, Stina Svensson, Gunilla Borgefors

Partners: Kim Dralle, Anders Björholm Dahl, Dralle A/S, Copenhagen, Denmark

Funding: S-faculty, SLU; Stiftelsen Mauritz Carlgrens fond

Period: 0612 -

Abstract: The focus of this Project is image analysis methods for identifying rot in log end faces. The purpose is to detect rot already while harvesting, or when the logs are in a stack waiting for transport. Logs are depicted using a standard color digital camera that can be mounted on a harvester or a vehicle. The goal is to find a robust method for detecting rot in timber suitable for practical use.

Bettina Selig, Cris Luengo, Gunilla Borgefors

Partners: Dept. of Forest Products, SLU

Funding: S-faculty, SLU

Period: 0709-

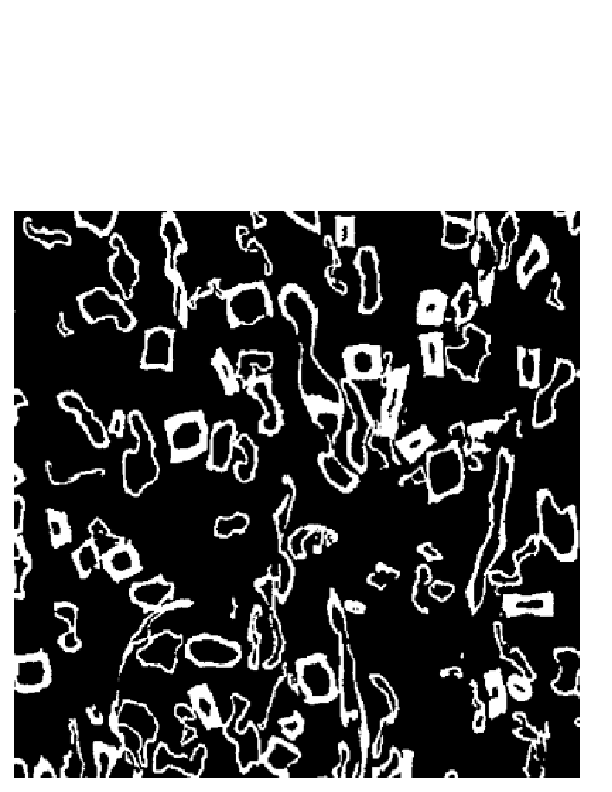

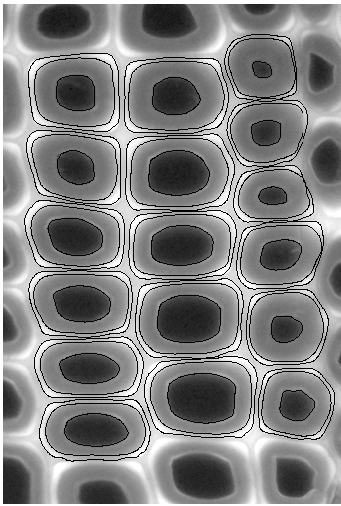

Abstract: The mechanical properties of wood fibres are important for many uses of this raw material. In compression wood the fibres are strengthened due to their high lignin content. On the other hand, the fibres become stiffer and more difficult to collapse which is negative regarding paper production. By observing the autofluorescence of lignin on fibre cross-sections with a UV-light microscope, the highly lignified zones in the fibre walls can be made visible, as they emit more light than other parts of the fibre walls. The goal of this Project is to develop an automatic method to detect and measure highly lignified areas and relate them to the area of the whole cell wall. The task is much complicated by the fact that edges are notoriously fuzzy in flourescence images. We have presented our progress at the 16th Scandinavian Conference on Image Analysis (SCIA 2009) in Oslo with the paper Segmentation of Highly Lignified Zones on Wood Fibre Cross-Sections (Figure 19). The next step is to improve and apply this method on a larger amount of images. Eventually the measured data can be used to improve the knowledge about compression wood.

|

Catherine Östlund

Partners: Innventia, Stockholm

Funding: VINNMER programme, Vinnova

Period: 0901-

Abstract: Studies of paper sheet structure characterisation, e.g. the distribution of fibres and fibre flocs, are commonly made using beta radiography or by splitting the paper in layers and study each layer. The three-dimensional (3D) structure of the sheet can from such data in some cases be estimated. The focus of this research Project is to develop a 3D paper structure analysis method based on image analysis, and to compare the results from two-dimensional analysis methods to those achieved with a 3D method.